Episode 286

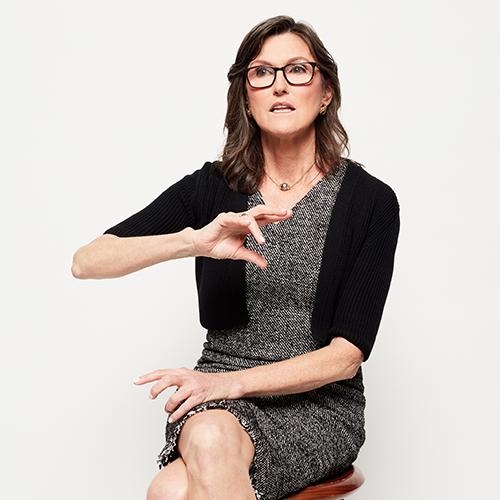

Lynn Martin, President of the New York Stock Exchange and Chair of ICE’s Fixed Income & Data Services business, joined us Inside the ICE House to reflect on International Women’s Day 2022 and preview her plan to expand the NYSE’s role as the nexus for economic growth and innovation. Part of this comes from expanding opportunities for those who have felt sidelined by the markets. Lynn outlines how she’s bullish on data, notably ESG data, to the corner of Wall and Broad and how it can be harnessed to make markets function more effectively with greater transparency.